The Studio | Derya Geylani & Egemen Kemal Vuruşan

- Onur Çoban

- Jul 4, 2023

- 3 min read

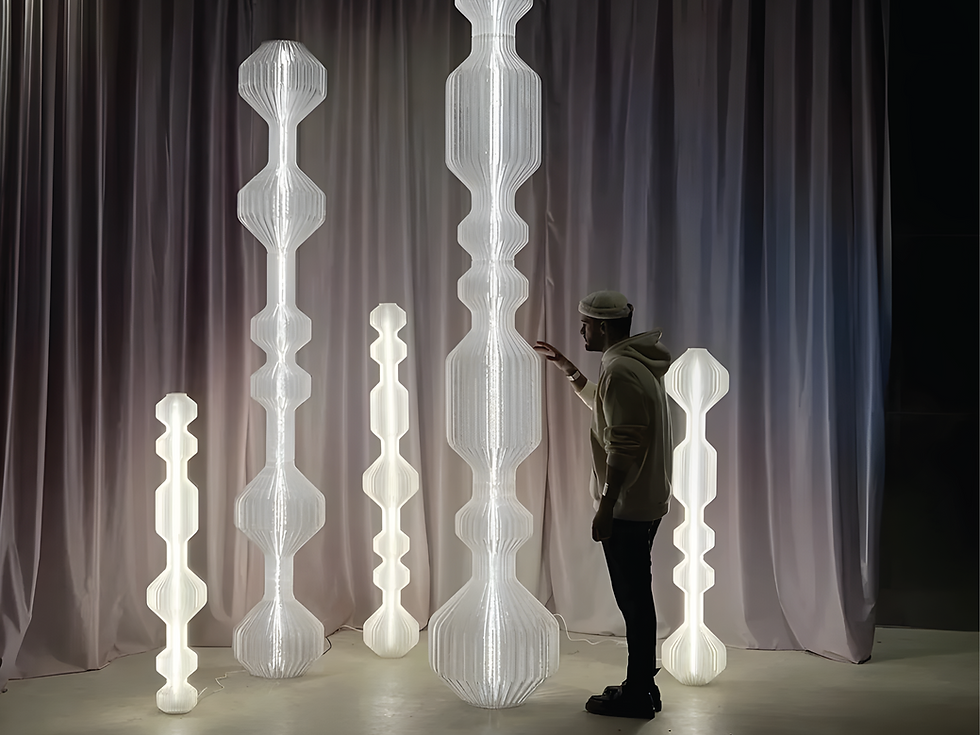

We talked with Derya Geylani Vuruşan and Egemen Kemal Vuruşan, who work in the same production field and explore glass as their primary material using different techniques and concepts. We discussed the intersections of their artistic approaches and the unique narratives they create on the common ground they find.

You are two artists who share a common denominator as the primary material but differ in processing methods. How does your approach to glass affect the feeling or forms you want to capture?

Although our common material is glass, working with different techniques enriches us in terms of thought. There are many techniques in the field of glass, and these techniques may differ for each design. Within the scope of joint projects, the method that can be applied in hot glass may not be compatible with the in-mold or flame-shaping technique. This situation leads us to criticize which technique we should use. While I think more pragmatically about the applicability and finalization of glass, for Derya, this situation can become a more romantic thought, and a sweet quarrel can occur.

Glass can be handled as modern as it is ancient and bent in line with the desired subject. When do you position your works on this plane with two different ends?

We think it is precious that glass, which has thousands of years of history and has been produced for use in history, is one of the primary materials of contemporary art today. At this point, we think blending our concepts and stories with a modern interpretation is fascinating by using traditional glass shaping methods that have been going on for centuries and presenting them to the audience with various installations and applications.

"A project journey that we start with a lot of excitement can evolve in a way full of surprises in the hot glass workshop. Our struggle with the fluidity and warmth of glass further reinforces our passion for the material."

To what extent does it transform your practice to work with a material that, by its nature, gives surprising results outside of its planned fiction in the production process?

It is a material that requires being prepared for surprise results. Especially hot glass is a material that needs to be started and finished during its production, unlike other materials. The material requires a specific temperature that needs to be protected during working in glass. When it falls below this temperature, cracking and breakage can occur, which we call "glass tension." Assuming that hot glass is also teamwork, we both need to have high performance and desire in the workshop. In addition, working with such a fluid and hot material significantly improves our focus, control, and, most importantly, our patience. At the same time, sometimes, we can use these surprising results as a tool for artistic expression.

How is the story you want to tell affected by the fascinating stage of glass processing?

A project journey that we start with a lot of excitement can evolve in a way full of surprises in the hot glass workshop. Our struggle with the fluidity and temperature of the glass further reinforces our passion for the material. This situation leads us to discover it more in the material. We can sail new routes in the workshop in each new design and project. This situation keeps the excitement between us and the glass fresh and improves us. The material we are discussing is so fascinating that you cannot think of anything other than the design you have planned during the work.

What topics focus on your productions in the same workshop that feeds each other's inspirations?

To put it in order of priority, discovering new places together, participating in visiting artist programs in Turkey and abroad, visiting museums, exhibitions, and fairs, and discovering new taste stops.

While fire and air are at the heart of your production method, which Dyson technologies facilitate this process in your workshop?

Especially in hot weather, we can make extra heating with propane gas to maintain the glass temperature in the glass workshop apart from the furnaces. As a result, the air quality in the environment decreases, and air temperatures can rise very high. Therefore, this situation could negatively affect our performance. We felt the air quality changed significantly from the moment we used the Dyson Purifier Cool Autoreact air purifier in the workshop. In addition to air quality, Dyson V15 Detect Absolute was one of our most essential assistants in the dusty workshop environment. We can say that it eliminated the problem of dusting and cleaning efficiently in our workshop, where there is constant movement.

Glass is a material that can be recycled and reused. Therefore, sustainability lies at the core of our art practice. Dyson's pioneering technologies also play an essential role in our preference for Dyson products.